Using a professional, experienced company to handle your air compressor and pipework design and installation saves you stress in the short term and money in the long term.

Our installations are speedy, safe, stress-free, and always carried out to the highest standards. Using a cheap installation service is almost always a false economy and can even be a safety risk.

We install:

- Air compressors – including the latest VSD and VSD+ Atlas Copco models

- Vacuum pumps – Atlas Copco VSD and other models

- Nitrogen generators – Atlas Copco NGP & NGP+

- Pipework – Atlas Copco AirNet, Parker Legris Transair, galvanised compressed air systems

- Dryers, filters and oil/water separators

- Pneumatics

- Chillers

Professional air compressor installation engineers

Our staff are directly employed by us and fully trained on the products they install.

Our dedicated Installations Manager and his team will manage your job from initial survey to final handover, so that your installation runs smoothly and efficiently, with minimum downtime or disruption to your working schedule.

You can consult and communicate with us at every stage of the process to ensure that the finished installation fully meets your requirements.

Air compressor installation process

- Initial meeting, site visit/survey

- Transparent quotation with clear recommendations

- Co-ordination of our team with other contractors

- Removal of old equipment where required

- Installation of temporary mobile compressor where required

- Dealing with any unexpected issues that arise during installation

- Adherence to health and safety guidelines

- Final quality check and sign-off

What you can expect from a PPS air compressor installation

- Clear communication – from initial quote to final quality check, to keep you in the loop and ensure that everyone involved understands what is required

- Problem solving – we’ll handle any issues that arise and work to resolve them as quickly as possible, including removing old equipment and arranging specialist transport and access equipment

- Good organisation – we’ll co-ordinate the installation team and subcontractors, holding site meetings where necessary

- High standards – completion of your job to a high standard, on time and in accordance with health and safety guidelines.

- Minimum disruption – we’ll work out-of-hours and/or put a mobile compressor on site to minimise disruption to your production schedule

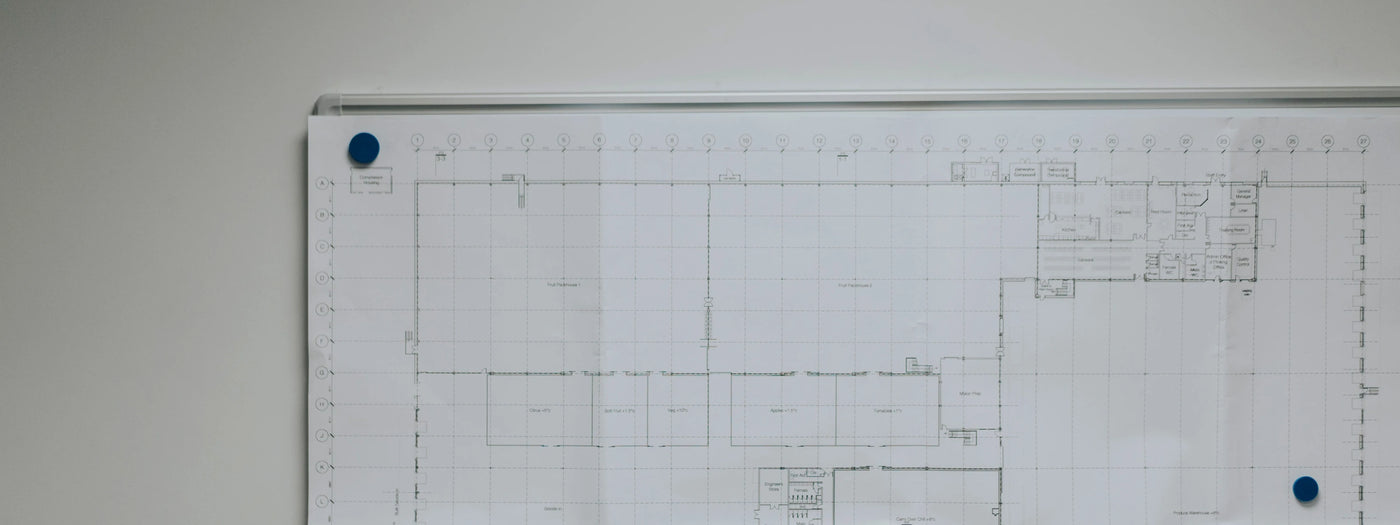

Pipework design and installation

Our pipework engineers are experienced in designing and installing smooth bore aluminium pipework or the traditional galvanised compressed air systems, from large new distribution mains to minor modifications.

Following a site visit, we can recommend the ideal piping material to suit the requirements of your business.

Ducting design and installation

For the design, installation and maintenance of ducting and extraction systems, contact our in-house ducting department. Our sheet metal ducting is fabricated at our premises by industry specialists.

We can create bespoke compressor discharge ducting, which can be used as part of a heat recovery system, venting hot air outside in the warm weather and directing it inside to heat your premises in the colder months.

Our inlet ducting can reduce the need for filters, with good quality fresh air vented into your compressor from outside. We also offer ducting for spray-painting booths and Clip Together ducting systems manufactured from galvanised steel with plasma-welded seams for reduced leakage.

Health & Safety

During your installation, PPS will follow industry health and safety guidelines. All our installations meet or exceed the latest BCAS best practice, health and safety guidelines and industrial standards, including legislation on pressure systems and the Environmental Protection Act (1990).

Respiratory air from a compressed air system must comply with COSSH regulation. Failure to comply can lead to a severe fine or prosecution under the requirements of BS4275:1997 – air supplied respiratory protective equipment. Our quality air testing service is specifically designed to check breathing air systems, analysing systems for water content, oil content, carbon dioxide, carbon monoxide and percentage oxygen levels.