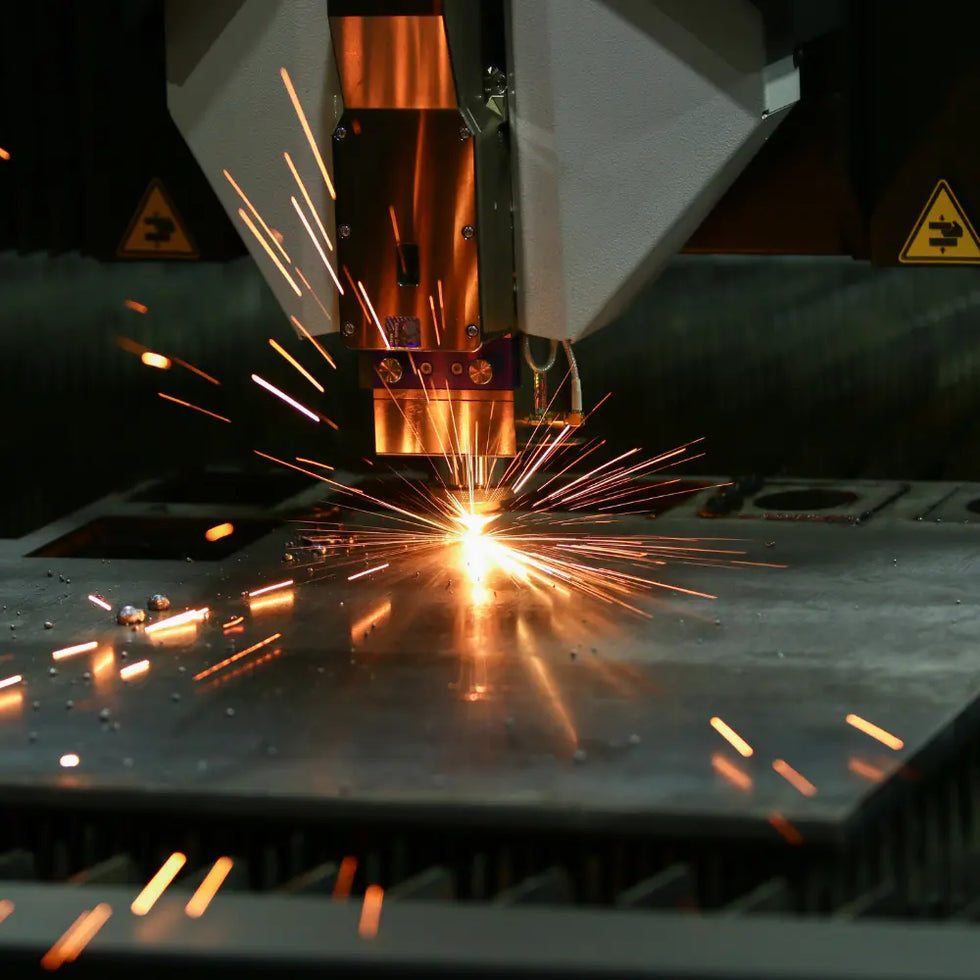

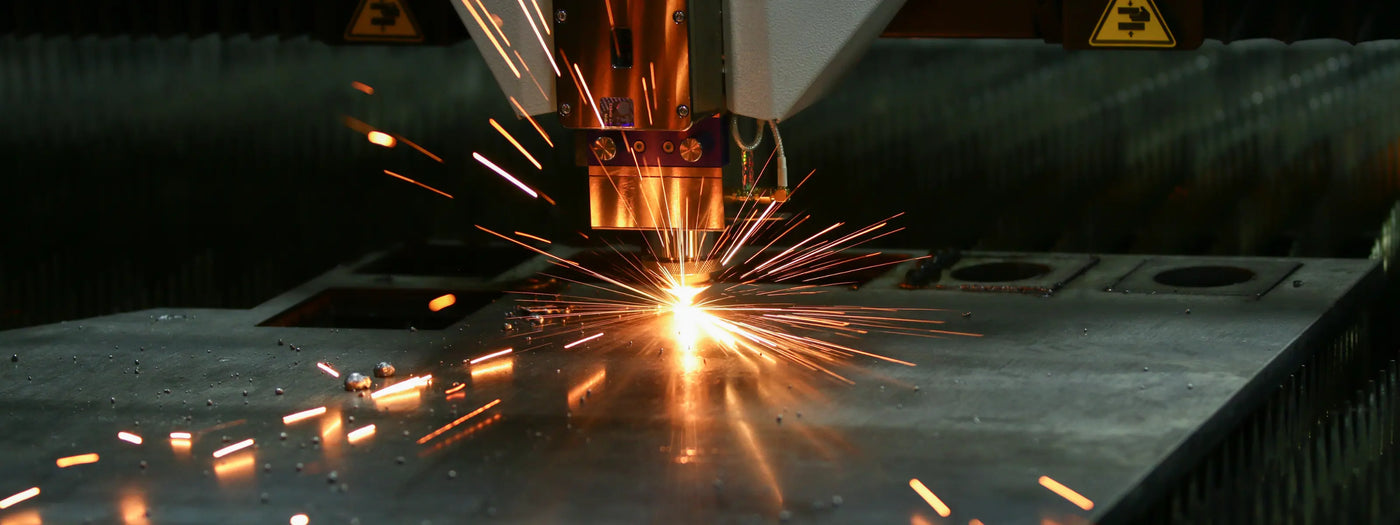

Compressed air and high purity nitrogen are an important part of the laser cutting process. We have a wide range of high-quality cost-effective solutions to help your process run smoothly.

The industry has seen a shift in recent years away from CO2 laser to fibre lasers. This shift has reduced demand for CO2 but increased nitrogen demand significantly. Fibre lasers use a lot more N2 so some sites have struggled with tank storage space.

As a result, we’ve seen an increase in demand for on-site nitrogen generation systems. These systems are usually delivered pre-assembled on a skid requiring only electrical and pipework connections to be made on site. These systems have their own compressor and use Pressure Swing Absorption (PSA) technology to absorb and expel oxygen to atmosphere. The twin tower design allows a continuous flow of nitrogen as one tower is in operation while the other is regenerating before switching over.

This leaves a mixture of argon and nitrogen with a purity up to 99.999% which is the same as a liquid or bottled supply. That said, we’ve found from our tests that a purity of 99.99% is sufficient for most users without discolouration.