Browse by industrial air compressor category

Atlas Copco

Atlas Copco G18 FF 18kw air compressor with dryer (10 bar)

£10,959.30Unit price /UnavailableAtlas Copco

Atlas Copco G11 FF 11kW air compressor with dryer (10 bar)

£8,774.10Unit price /UnavailableAtlas Copco

Atlas Copco G7 FF 7.5kW air compressor with dryer (10 bar)

£6,656.40Unit price /Unavailable

The full Atlas Copco industrial air compressor range available through PPS

Install the correct size industrial air compressor. Start with an energy audit.

Whatever industrial air compressor project you are undertaking, having an accurate understanding of your site’s compressed air demand means you can select the right compressor for your application.

Don’t buy like for like based on the kW rating. Do buy based on the correct pressure and flow for your site.

Take advantage of the free data logging and site survey offered by PPS.

This service is non-intrusive and does not interrupt production. This will show you an accurate account of your plant’s compressed air demand, pressure and cycle over a seven-day period, identifying energy costs and where savings can be made.

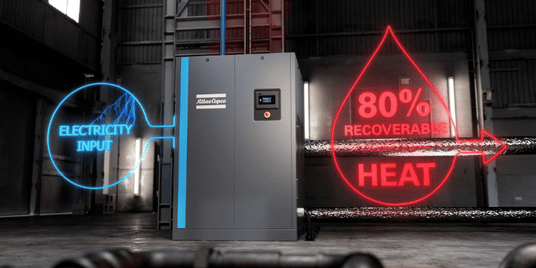

Energy-recovery heat exchangers for industrial air compressors

All new compressors can be specified with factory-fitted, warm water energy-recovery heat exchangers for processes such as pre-heating boiler feed systems, heating radiators or washroom facilities. We can also supply standalone energy recovery units for existing air compressor installations.

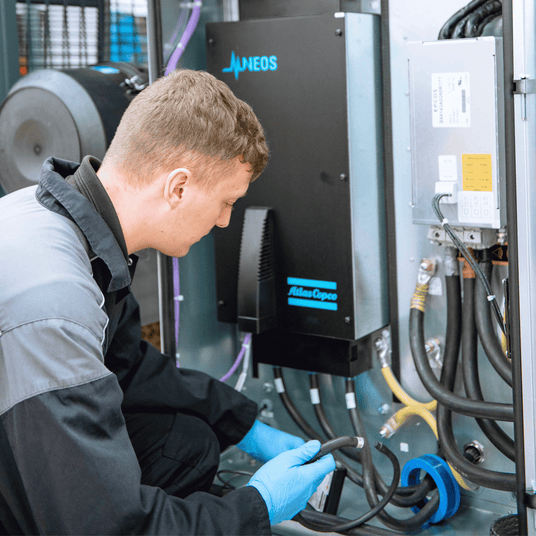

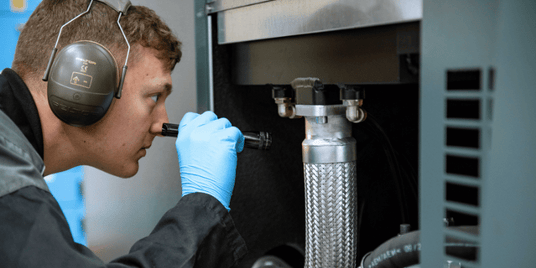

Industrial air compressor servicing and warranties

The industrial air compressors we supply are available with warranties for up to seven years. Customers can also take advantage of our air compressor service options, from routine maintenance to emergency breakdown cover – all of which is carried out by manufacturer-trained staff.

Industrial air compressor case studies

See all case studiesIndustrial air compressor advice

Frequently Asked Questions for Industrial Air Compressors

Which compressor is best for industrial use?

Which compressor is best for industrial use?

The best compressor for industrial use depends on your application. For continuous, high-demand operations, a rotary screw compressor is typically the most efficient and reliable. If you need clean, oil-free air for food, medical, or pharmaceutical use, an oil-free compressor is ideal.

What size industrial air compressor do I need?

What size industrial air compressor do I need?

To choose the right size, calculate your total air demand (CFM) and required pressure (bar/psi), then factor in any future expansion. Under sizing can lead to pressure drops; over sizing wastes energy. Our team can help you assess your exact needs.

How do I choose the right air compressor?

How do I choose the right air compressor?

Start by identifying what you need for your application, air volume, pressure, and duty cycle. Consider energy efficiency, noise levels, space, and whether you need an oil-lubricated or oil-free compressor. We offer expert advice to match you with the most suitable industrial air compressor.

How much does it cost to install an industrial air compressor?

How much does it cost to install an industrial air compressor?

Installation costs vary based on compressor size, site conditions, pipework, and whether accessories like dryers or tanks are needed. PPS has an installation team that handles all your piping and ductwork needs, providing tailored quotes with no hidden costs.

Your air compressor supplier across Yorkshire, Derbyshire and the north of England

We have five branches based across the UK:

- Brighouse, West Yorkshire (Head Office)

- Sheffield, South Yorkshire

- Hull, East Yorkshire

- Alfreton, Derbyshire

- Knowsley, North West

We have been servicing customers as an air compressor supplier throughout the north of England for many years. We’ve built up a reputation for excellent customer service in areas such as Bradford, Chesterfield, Derby, Halifax, Huddersfield, Leeds, Manchester, Nottingham, Rotherham, Wakefield and beyond. Thanks to our experience, our location and not to forget our award winning dedicated team, we have become the go-to company for anyone looking to buy or hire air compressors in the north.