Which type of compressed air dryer should I buy?

Whatever your application, we can offer advice on the best equipment for your needs from our range of dryers, filters and oil/water separators.

There are models to fit in restricted spaces or where flexible mounting is required, as well as in areas where there is high vibration or fluctuating/extreme temperatures. Dew points range from the standard 3°C down to -70°C.

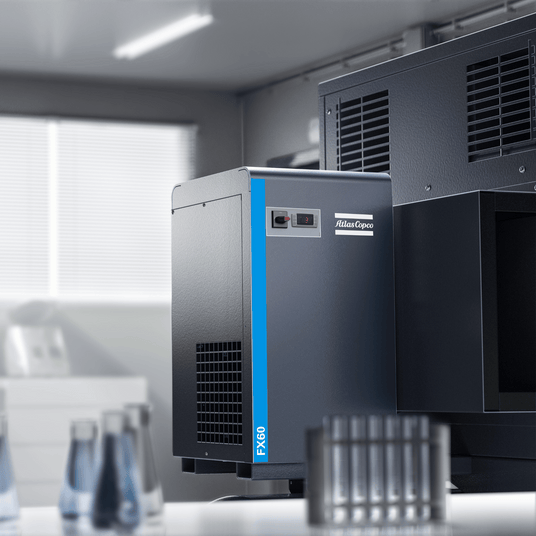

As a branch of Atlas Copco Compressors UK, we supply the latest energy-efficient dryer models, including:

- Refrigerant air dryers – these have two heat exchangers (air-to-air heat and air-to-refrigeration), which prevent condensate forming.

- Desiccant air dryers – also called adsorption dryers, regenerative dryers or twin tower dryers. The air is filtered through internal towers, with a desiccant to remove the water. They offer heat regeneration, air and steam applications.

- Membrane air dryers – water vapour is removed by a bundle of membranes with hollow fibres, then vented outside the machine by gas or collected on the membrane coating for disposal.

The full range of compressed air dryers available through PPS

Compressed air dryer supply and installation

Air dryers, line filters and condensate management systems such as oil/water separators can be supplied and installed for you with the minimum of fuss and a manufacturer’s warranty for your peace of mind.

With optimum reliability and minimum maintenance, our energy-efficient air dryers will give you a fast return on investment.