Key benefits of on-site nitrogen generation

- Significant cost savings over traditional supply

- No delivery, rental, or handling fees

- Reduced health and safety risks from gas deliveries

- Continuous, dependable nitrogen supply

- Long equipment service life with minimal maintenance

- No boil-off losses or returned partially used bottles

- Make nitrogen overnight for use during the day

- No production downtime for bottle changeovers

Nitrogen generation for your industry

Whether used for back pressure, modified atmosphere packaging, or purging systems, nitrogen plays a vital role across industries:

- Food and drink: packaging, preservation, breweries

- Pharmaceutical and healthcare: sterile packaging, lab processes

- Electronics: soldering, testing, component storage

- Chemical and plastics: inerting, blanketing, safety

- Laser cutting: precision cutting with minimal oxidation

- Glass, ceramics and steel: processing and atmosphere control

- Construction and fertiliser: propellant and stabiliser use

Wherever your industry uses nitrogen, an on-site nitrogen generator from PPS ensures a safer, more efficient, and cost-effective supply.

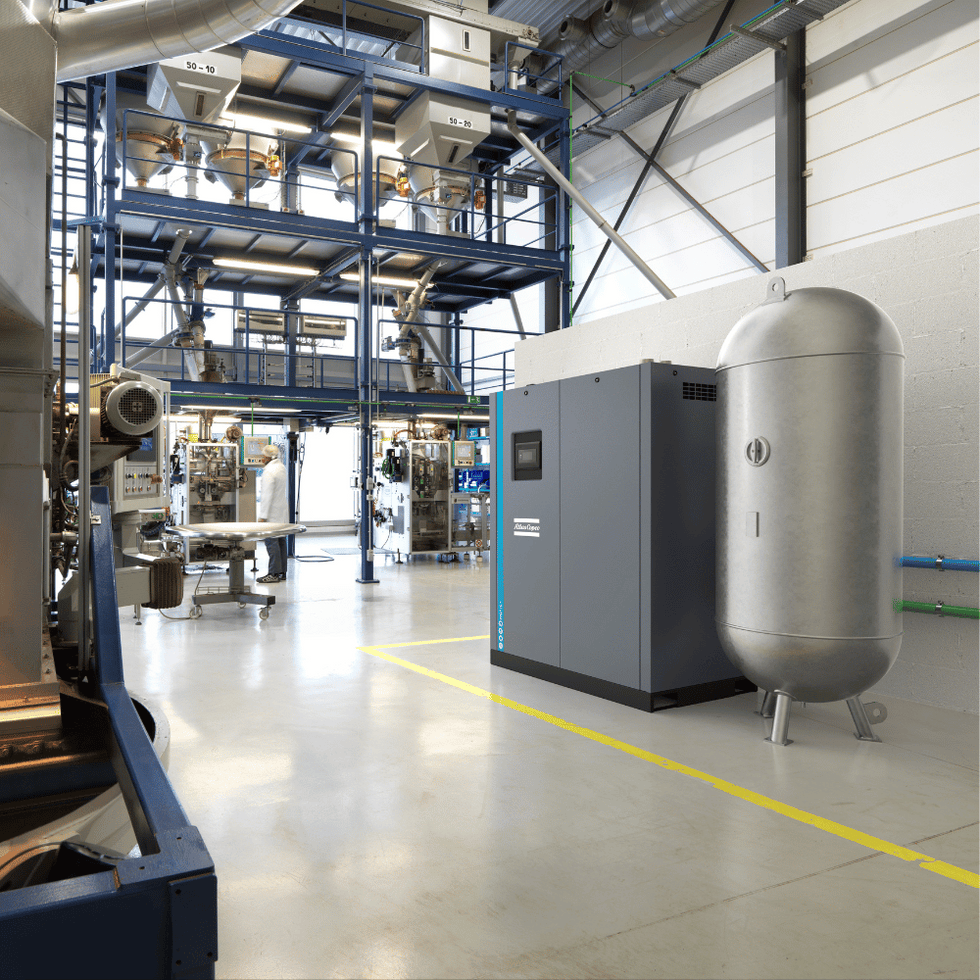

The full range of Atlas Copco nitrogen generators available through PPS

Nitrogen generator case studies

See all case studiesFrequently Asked Questions for Nitrogen Generators

What is a nitrogen generator?

What is a nitrogen generator?

A nitrogen generator is a system that separates nitrogen from compressed air to produce high-purity nitrogen on-site. It provides a reliable and cost-effective alternative to bottled or liquid nitrogen.

How much does a nitrogen generator cost?

How much does a nitrogen generator cost?

The cost depends on the flow rate, purity, and system size. Small units start from a few thousand pounds, while larger industrial systems may cost tens of thousands. PPS can provide a tailored quote based on your needs.

Do nitrogen generators need compressed air?

Do nitrogen generators need compressed air?

Yes, nitrogen generators require a compressed air supply. The air is filtered and processed to separate the nitrogen, so pairing the generator with a reliable air compressor is essential.

How much nitrogen can a nitrogen generator produce?

How much nitrogen can a nitrogen generator produce?

Output varies by model, ranging from a few litres per minute to hundreds of cubic metres per hour. PPS can size a system based on your application, usage, and required purity.