Clean air is needed for treating water and wastewater. Oil-free air blowers are a wise choice as they ensure that no oil from the blowers will be added to the treatment processes. For example, when counting on an air supply to keep the bacteria alive, oil contamination is not desirable. The air in conventional activated sludge systems must be oil-free to avoid contamination of the water, and oil-free air prevents filter media from becoming dirty and unusable in filter backwashing. If a blower is ISO 8573-1 (2010) Class 0 certified it is a guarantee that the air is not contaminated by oil during the compression process.

The starting point is a thorough analysis of an installation and recognition that application characteristics are key to selecting the right technology. In the decision process, there will undoubtedly be one or more aspects that might take precedence over others.

Apart from finding a blower technology that matches the airflow and pressure needs of a specific water or wastewater treatment process, other factors such as initial investment cost or return on investment will also affect the search for the right air blower technology.

Key factors that should be taken into consideration include:

Flow and Pressure

A correctly sized blower installation will help to achieve a more energy-efficient process. In most wastewater treatment plants, different amounts of air are required during the day, and blowers are even sized for peak demands which don’t occur frequently. Selecting a blower on one single peak point can lead to lower efficiencies at real day-to-day operating points.

Operational costs and total cost of ownership

The capital cost of a low-pressure aeration lobe blower may represent less than 5% of a total wastewater plant’s investment. This may appear to be an attractive proposition, but blower running costs are a far more significant factor and are likely to constitute up to 70% of the electricity costs for an entire wastewater treatment plant. This is because the aeration blowers need energy to run 24 hours a day in supporting the biological processes. They supply the right amount of oxygen to micro-organisms, maintaining their constant, balanced performance within the plant. It follows that, when considering the total cost of ownership of a blower installation, the need to seek an energy-efficient solution should be at the top of the list.

Application conditions

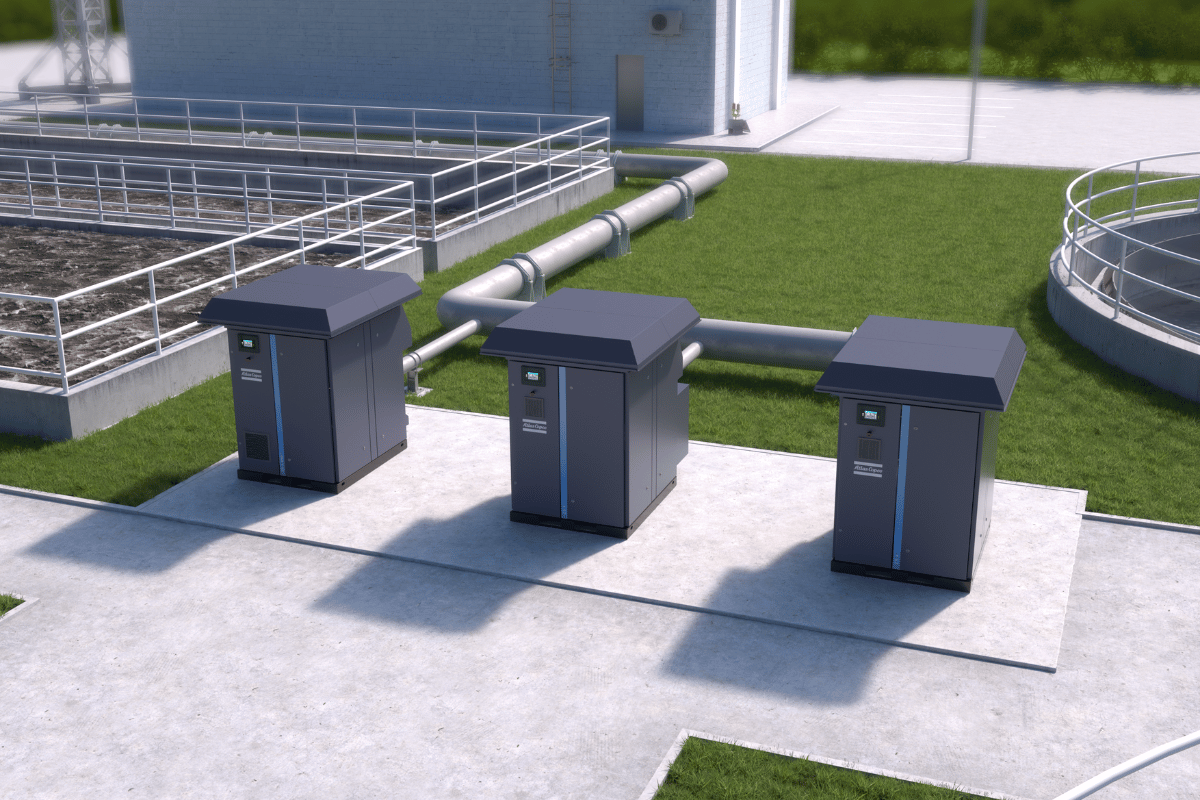

Site characteristics have a bearing on blower choice. For example, limited space availability for a blower installation might dictate the choice of a technology offering a smaller footprint and lower noise level. On the other hand, the application criterion of lower energy costs may be best met by a more energy-efficient technology that comes with a higher capital cost but a far lower lifecycle cost.

Operating noise levels

A feature of the latest generation of low-pressure blowers is intelligent baffle and canopy design that provides reduced sound levels for an improved working environment. Consequently, installation costs are reduced as there is no need for the provision of noise-insulated rooms and doors. Outdoor variants are also available to give the flexibility of having an outdoor installation.

Service and lifetime support

When it comes to routine maintenance and service support, some older blower technologies may require units to be serviced, repaired or refurbished offsite. Advanced design developments in the latest oil-free, low-pressure blowers now see the inclusion of low maintenance components, extended on-site service intervals, and the benefits of lifetime customer support plans, and the possibility to do maintenance and inspection from the front and back of the blower.

To find out more about the Atlas Copco low pressure blowers that PPS supply, install and maintain you can view the product page here, give us a call on 01422 321 772 or fill in an enquiry form. We’re ready to help with your next project.