The benefits of compressed air filters and air treatment are wide ranging and include:

- Better quality compressed air

- Improved efficiency and performance of components leading to lower energy bills and reduced carbon footprint

- Preservation of the system, reducing breakdowns and maintenance costs

- Longer service life of associated equipment, such as air tools, cylinders and valves

As experts in compressed air and air treatment products, we can offer advice on the options for protecting your equipment and processes. All of the advice we offer you will be completely impartial, and will be based on our industry experience and the most cost-effective solution for your needs.

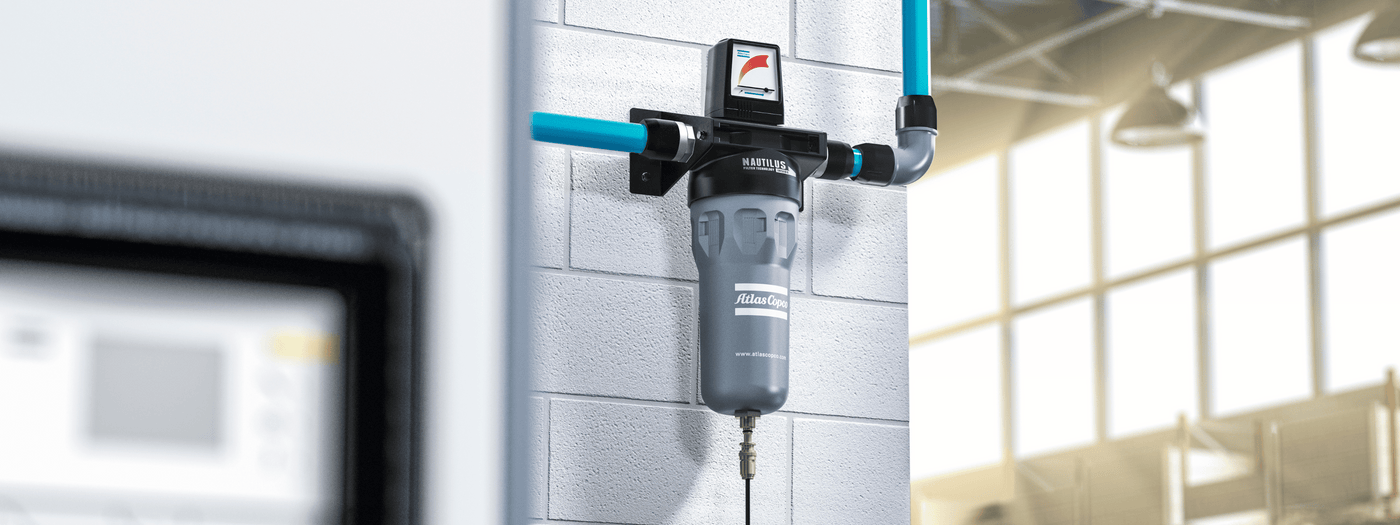

Oil-driven compressors should be linked to a filter and a dryer, but even specialist Atlas Copco medical compressors should have a filtration system attached to ensure air purity.